- Tutti

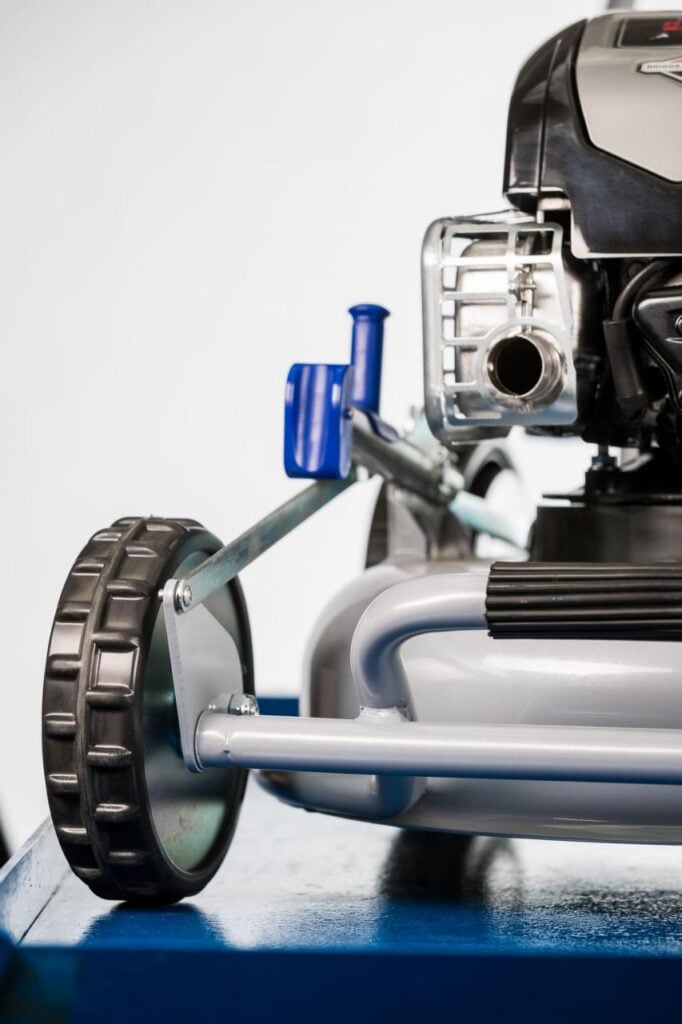

Reinforce axles

The steel axles are characterized by sections of reinforced tube to grant impact resistance and an efficient mowing even after years of use.

Steel wheels

The wheels with steel rim and hub are manufactured to last over time. The double ball bearings grant ease of movement even on extremely difficult terrain. The treads have been designed to meet the need of every model and user.

Patented blade

The patented blade is manufactured with a special production process, which enhances strength and durability. The material thickness and the sharpening method assure a 3/4 times longer life span than conventional blades.

Steel frame

The supporting frame is manufactured with a steel tube, which is welded to the mowing deck to form a unique solid part (registered utility model). This increases the overall strength and rigidity of the lawnmower and helps reducing vibration.

Steel mowing deck

The mowing deck is completely smooth and manufactured with a 3 mm thick, powder coated steel. This provides sturdiness and allows a proper centrifuge of the grass.

Centralized mowing height adjustment

The rapid height adjustment on the four wheels is possible using a single lever. With a single movement, it is possible to set the desired height quickly and easily.

Electric start

GRIN models start at the touch of a button. A simple press of the start control and you're ready to cut - fast, simple and effective.

82v battery motor

Powerful like a combustion engine, easy like an electric motor.

Briggs & stratton professional engine

Power and reliability combined with ease of use

Kawasaki professional engine

Designed for the most demanding professional

Vertical storage

70% of space saved in your garage

Mow n’stow vertical storage

70% of space saved in your garage even with full tanks

Ready Start

automatic starter to start the engine on the first try

Ready start

automatic starter to start the engine on the first try

Pressurised lubrication on slopes

To mow even on slopes over 20°

Professional traction

Professional with 2 speeds to adapt to different conditions

Engine protection cone

to minimize impacts on uneven terrain

Grip GRIN maxi

to overcome obstacles on uneven terrain

Anti-vibration handlebar and comfort levers

for more comfort in case of intensive use

Foldable handlebar

Thanks to two easy levers, it is possible to fold the handlebar for storage in little space and an easy transport.

Anti-vibration quick regulator

Two sturdy Nylon regulators allow the adjustment of the handlebar height according to the one of the user. Grin has also studied a vibration absorption system inside the new regulators to grant much more comfort in case of intensive use.

Frame designed for transport

The Grin frame has an ergonomic shape designed to improve the maneuverability of the mower and is suitable for transport. Two handles allow the user to lift the machine easily in case of stairs or inconvenient areas of the garden. With folded handlebar, GRIN can also fit in the smaller cars to be easily transported.

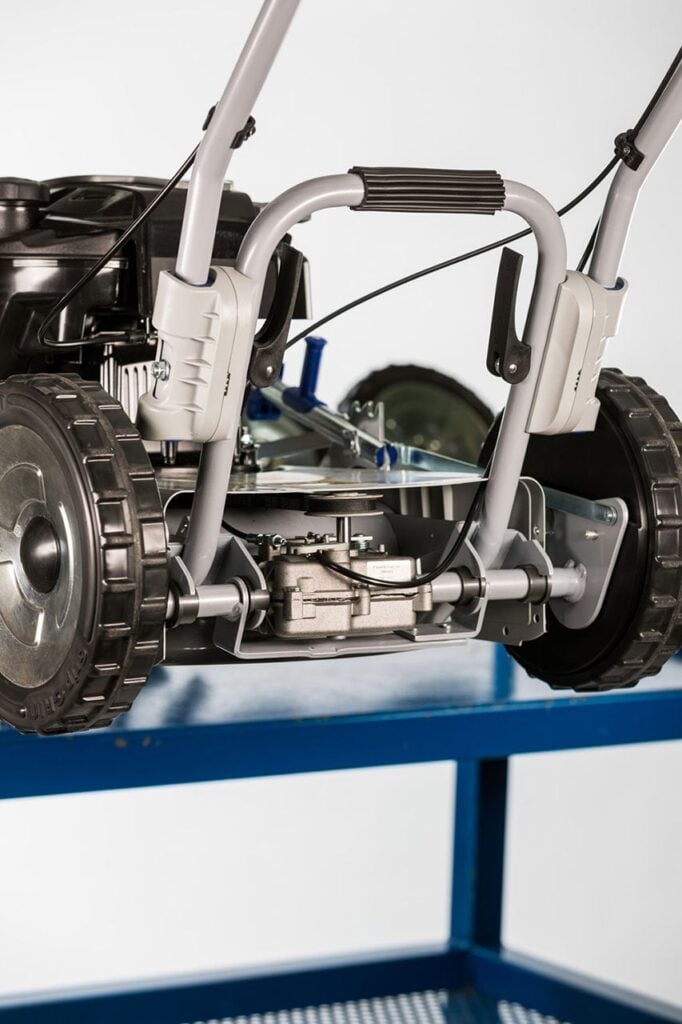

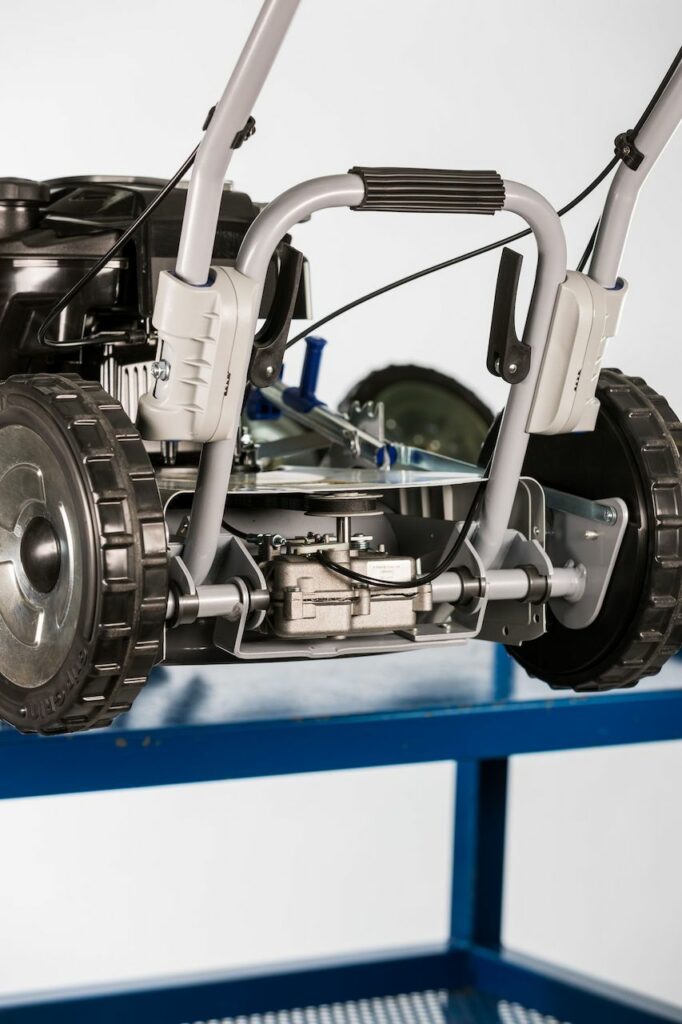

Suspended traction

The traction in oil bath in aluminum casing works in suspension reducing the load on the drive axles. The drive belt is completely protected by a specific cover. It tends automatically with the movement of the traction, thus minimizing the wear.

Tall grass

Flower meadow

Rustic meadow

Well maintained lawn

Leaves

Weeds

Easy starter

The high range equipment of the GRIN motors allow an effortless and immediate start. New technologies make the use easy and intuitive by minimizing ordinary maintenance operations

Electric Start

The powerful professional Briggs & Stratton engine is equipped with both starter cord and electric start with key

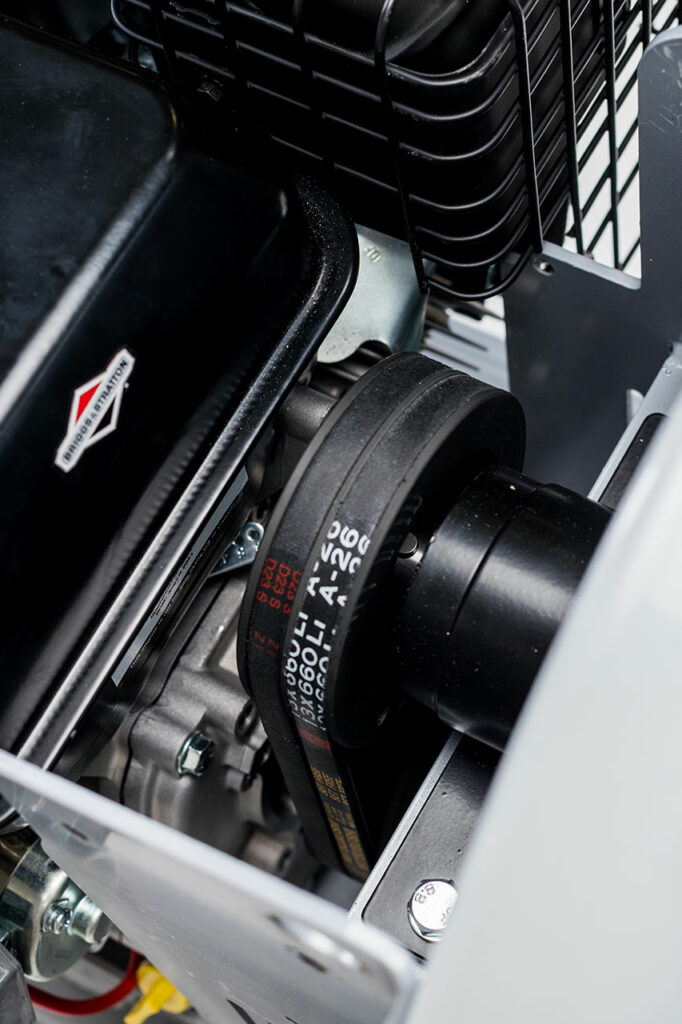

V-Belt

The trasmission system has been developed to last in time and it is equipped with a V-belt.

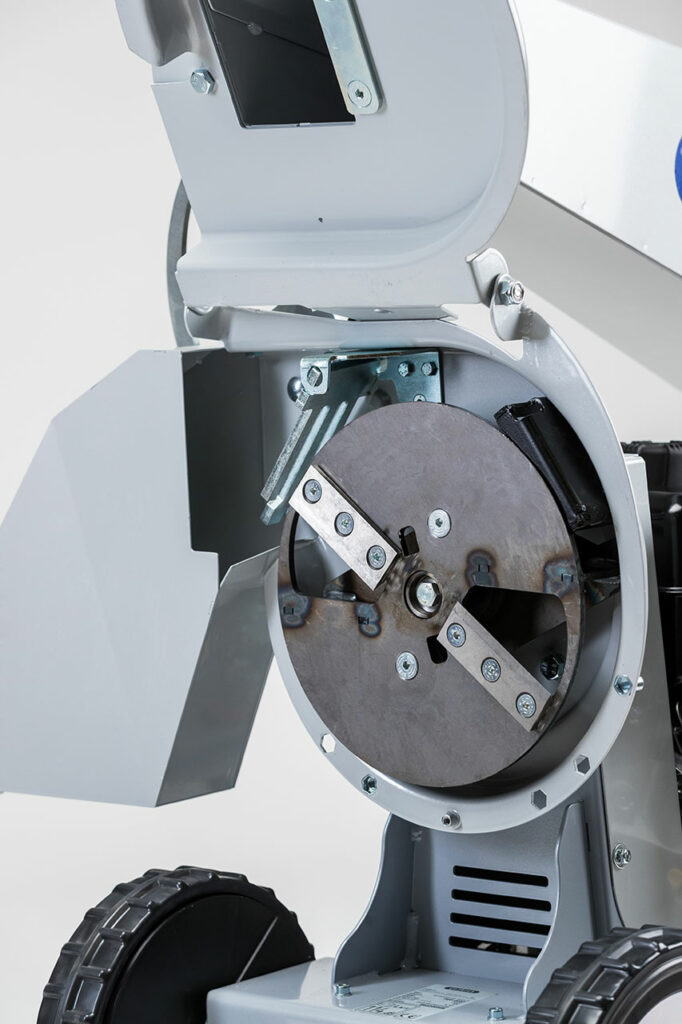

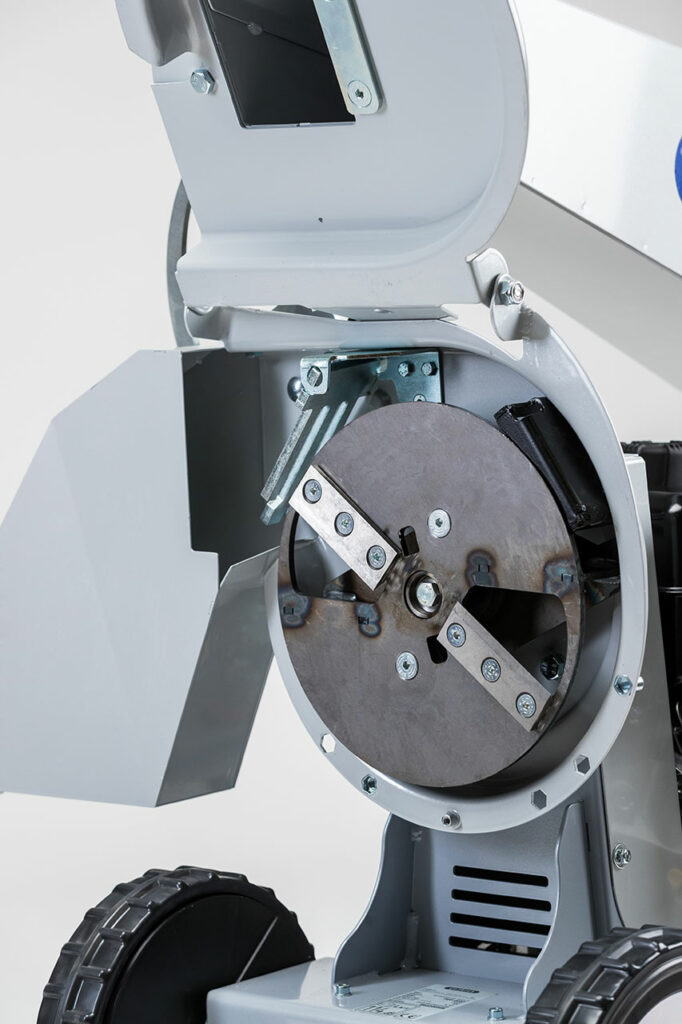

GRIN cutting disk

The GRIN cutting system, with blades and flails, is made of steel and grants fine chippings even of difficult pruning, for example if humid and fibrous.

Double V-Belt

The transmission system has been developed to last in time and it is equipped with a double V-belt ideal for intensive use.

Easy handling

The machines of the BIOCH range are developed to be quickly and easily moved.

Swiveling discharge chute

The 360° swiveling discharge chute with quick adjustable system is very wide and allows you to discharge the processed material directly onto a van or a trailer

Steel frame

The high-quality steel frame grants durability, professional performances and the safety of the user.

Opening hopper

The feed hopper is equipped with a quick opening to clean the cutting system and for an easy transport even by car.

GRIN cutting disk

The GRIN cutting system, with blades and flails, is made of steel and grants fine chippings even of difficult pruning, for example if humid and fibrous.

Electric start

The powerful professional Briggs & Stratton engine is equipped with both starter cord and electric start with key

Steel frame

The high-quality steel frame grants durability, professional performances and the safety of the user.

Easy handling

The machines of the BIOCH range are developed to be quickly and easily moved.

Standard ANTIstress system

The ANTIstress system consists of a control unit that detects the engine effort and transmits information to the loading roller.

In this way, the loading speed is optimized in case of material hard to process.

The ANTIstress control unit doubles as an hour counter to register the actual use of the machine.

With hydraulic tracks

BIOCH120 can be easily moved thanks to two hydraulic tracks developed for this specific application.

The hydraulic handling is possible thanks to two levers on the dashboard that grant smooth movements on lawns but are, at the same time, effective on uneven terrain and wood areas.

BIOCH120 has a driving speed of 2.5 km/h and is effective on slopes up to 37%.

The tracks are 105 cm long and the track width is 90 cm.

Compared to other shredders, the length and track width are very wide, increasing in this way stability and safety.

Single engine to shift the center of gravity downwards, increase stability and driving sensibility

The single 627 cc Briggs & Stratton Vanguard engine serves both for handling and for operating the cutting system.

The position of the engine is developed to shift the center of gravity downwards in order to increase stability to:

- Avoid overturning

- Improve driving sensibility

The single engine also optimizes consumption and maintenance of the machine.

Reduced dimensions and low weight

BIOCH 120 is only 109 cm wide and approximately 174 cm long when the hopper is folded. (290 cm with open hopper)

These dimensions are very compact for this machine type and allow you to transport BIOCH 120 even on the smallest trucks. It is also possible to store the machine in a small space.

The weight of 550 kg is low, even if the construction is very solid.

Discharge chute with wide inlet

The processed material is discharged through a very wide discharge chute of approximately 40 x 20 cm.

Inside the discharge chute there are no bottlenecks that can obstruct the material outflow.

The shape of the discharge chute has been developed to make the most of the powerful airflow created by the radial blades of the shredding system.

360° swiveling discharge chute

The 360° swiveling discharge chute with quick adjustable system discharges the material at a height of about 195 cm.

A deflector allows you to adjust the direction of the discharged material for a proper loading onto vehicles.

The generous dimensions and the angle of the discharge chute are developed, once again, to facilitate the discharge of chipping, avoiding clogging issues even when the material is green and fibrous.

Cutting of dry, green and fibrous wood

Optimal performances even with difficult and fibrous pruning such as palm or olive trees.

The shredding system, combined with the power of the Briggs & Stratton VANGUARD 627 CC 23HP two-cylinder engine, does not fail even with the most difficult material.

The engine start is electric, but also corded if required.

The integrated 8.5 L tank allows you to work without interruption over a long period.

GRIN cutterhead system with 4 knives and radial blades

The heart of BIOCH120 is the GRIN cutterhead system, that weighs 50 kg.

This system is equipped with four heavy-duty, hardened steel knives that grant finely cut material.

The radial blades placed inside the cutterhead can produce a strong air flow that has the dual task of:

- Quickly ejecting material once processed from the cutterhead to avoid clogging and speed up work

- Pushing the material out of the discharge system to avoid clogging even when it is wet and/or fibrous.

A flap allows the inspection of the cutterhead (and the roller) for cleaning or maintaining the cutting blades. The bearings dedicated to transport have a cast-iron support with grease nipple.

Up to 120 mm

GRIN BIOCH120 is suitable to chop pruning up to 120 mm diameters.

The high-quality chipping is uniform, ideal for reuse without any further processing.

The transmission is granted by a double toothed belt with centrifugal clutch.

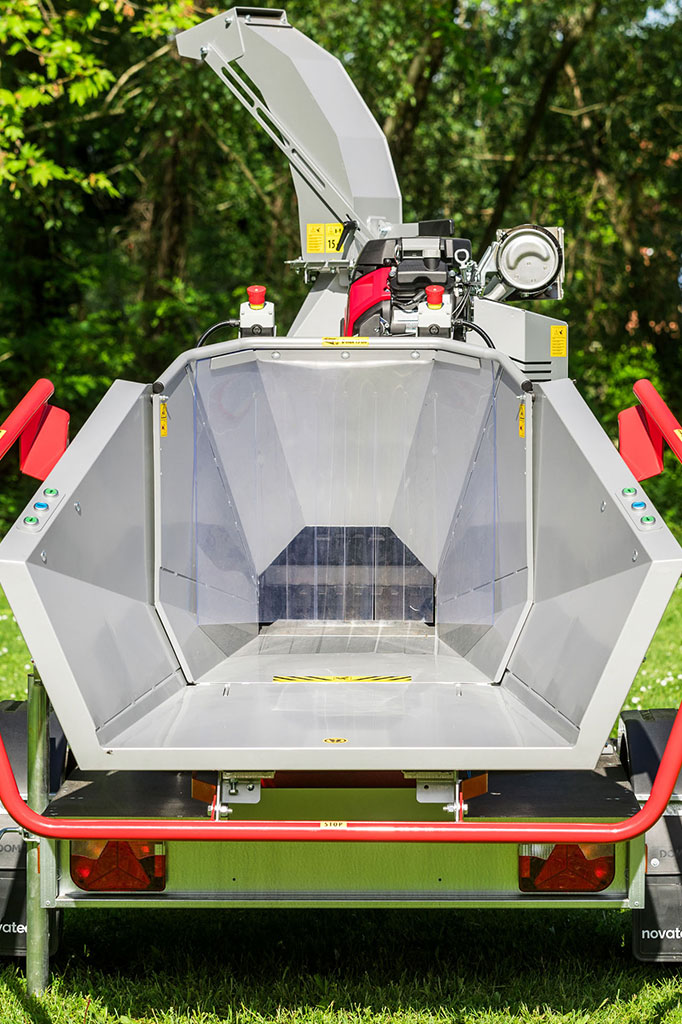

Maxi hopper

The GRIN BIOCH120 hopper has a very wide inlet (96 x 43 cm) to allow the operator to easily introduce material.

It can be easily folded in two points for space-saving transportation.

On the hopper there are the emergency button, the machine restart button and the commands to reverse the direction of the loading roller.

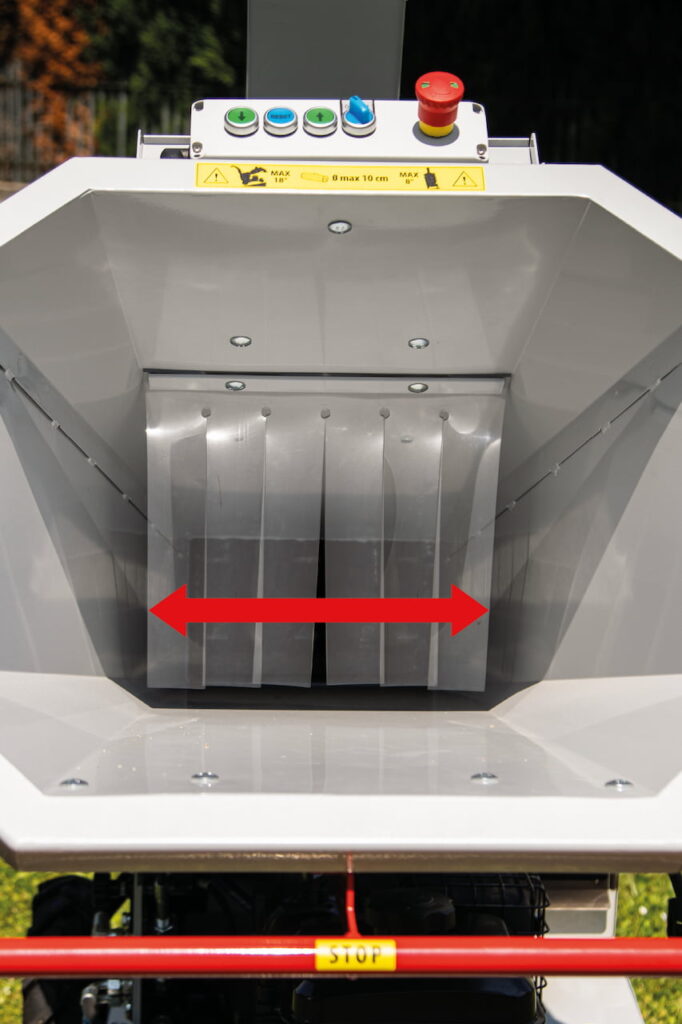

Hydraulic loading roller with adjustable speed

The toothed loading roller allows the transport of the material from the hopper into the GRIN shredding system

The roller is made of very resistant steel and powered by a high-performance hydraulic pump.

An external control allows you to change the speed in order to adjust the amount of material to be processed according to the type

Wide cutting system inlet

Once loaded, the material passes through the lower part of the hopper before entering the shredding system. Once again, the generous dimensions

(33.5 x 32 cm) make the introdcution of particularly leafy material very easy.

In this way, even the most difficult pruning are quickly shredded by GRIN BIOCH120 with a significant reduction in working time.

MAXI-3 mowing deck

The quality of the mowing system without grass bag is granted by 3 separate GRIN mowing decks laid out in a triangle

Engine

The position of the engine, directly on the mowing deck, provides maximum efficiency and reduces the loss of power, granting grass pulverization even under difficult conditions.

Quick cleaning

The cleaning system, equipped with graft for water hose, is integrated into the mowing deck and allows a quick maintenance.

Electric mowing height adjustment

Button on the dashboard, that can also be used with the engine switched off, micrometric adjustment, from 25 mm to 115 mm (measured on tarmac).

User-friendly

GRIN XM is only app. 140 cm long and is handy in tight spaces, practical for transport on vehicles

The weight is very low

the weight varies between 180 kg and 215 kg and this allows, minimal soil and turf crushing, maximum agility, less fuel consumption.

3 machines in 1 thanks to the ON BOARD plate

Grin XM can be equipped with the optional ON-BOARD connection plate for the quick coupling and uncoupling of two accessories that allow a different configuration

STAND ON

STAND ON is an accessory that allows to use XM in the standing man on board version.

RIDE ON

RIDE-ON is an accessory that allows to use XM in the seated man on board version.

GRIN EASY DRIVE

GRIN EASY DRIVE is an innovative Zero-Turn traction, that grants ease of use, effectiveness on slopes and respect of the soil and the turf

Quick maintenance flap

A flap allows the inspection of the cutterhead (and the roller) for cleaning or maintaining the cutting blades. The bearings dedicated to transport have a cast-iron support with grease nipple.

Reduced dimensions and low weight

BIOCH 120 is only 109 cm wide and approximately 174 cm long when the hopper is folded. (290 cm with open hopper) These dimensions are very compact for this machine type and allow you to transport BIOCH 120 even on the smallest trucks. It is also possible to store the machine in a small space. The weight of 550 kg is low, even if the construction is very solid.

Large hopper

The hopper of BIOCH150 is one of the largest on the market. Thanks to its 1200 mm inlet, it’s possible to load even very leafy branches. Loading is done through two maxi-sized hydraulic rollers: the 420 mm width of the loading inlet allows even branches with forks to be processed without interrupting work. Furthermore, a large amount of material can be introduced into the cutting system at the same time to increase productivity. Two operators can load the material without hindering each other or without clogging the machine. The hopper's height from the ground of about 700 mm allows the operator to introduce the branches without having to raise them too high off the ground, working in a perfectly ergonomic position.

Double hydraulic roller

The double hydraulic loading roller, with variable speed, is made of especially resistant materials to process even the hardest wood. Branches with forks, particularly long branches, significant amounts of branches or hedges are dragged by the force of the two rollers.

GRIN ANTIstress PRO system

The movement of the rollers is regulated by the GRIN ANTIstress PRO system: it automatically manages the backward movement of the rollers, allowing the material to move backward for a few centimeters and then resume the chopping process a few seconds later. This electronic control is essential to maintain a high working speed even when the machine is overloaded. The GRIN ANTIstress PRO system also allows 3 different settings depending on the material that is going to be processed.

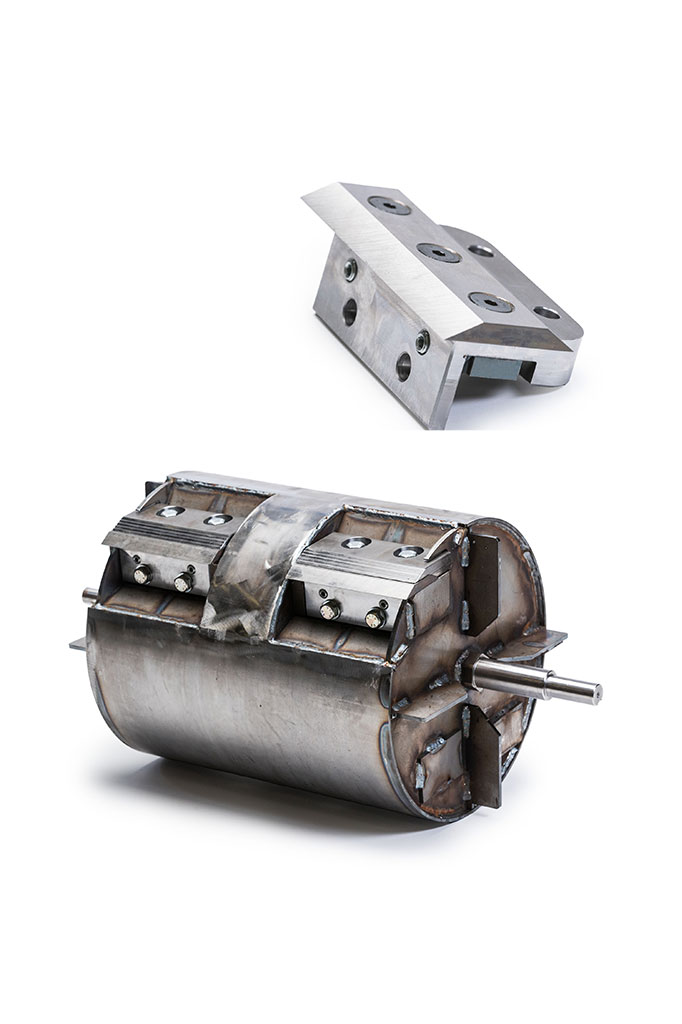

GRIN ULTRACUT cutting system

The GRIN ULTRACUT cutting system is the heart of the machine. It consists of a set of knives placed on a closed cylindrical cutterhead On the outer part, some radial blades are designed to generate the airflow needed to eject the processed material. The GRIN ULTRACUT cutterhead: - takes full advantage of the engine power - decreases clogging caused by overloading - reduces the consumption of the machine - guarantees incredible working speed

Openable chimney

It only takes a few seconds to access the cutting apparatus and perform maintenance such as changing knives. The operator can rely on a large access area, positioned to work effectively and safely.

Removable blade inserts

The knives are not simply screwed to the cutterhead but are placed on removable inserts. These inserts enable: - A fast replacement of knives that avoids downtime - A perfect and precise adjustment between knife and counter-knife that ensures perfect shredding even after many years of use. The operator can also have spare inserts to change knives in few seconds and directly on site.

Exhaust chimney

Material is ejected through an adjustable discharge chute, swiveling at 270 degrees with a quick lever. The height of the discharge chute, 2,350 mm from the ground, makes it possible to load wood chips even into the highest van levels. While, thanks to the deflector, it is possible to direct the flow of material. The last part of the discharge chute folds down with a quick, tool-free command for transport when hauling the machine.

270° swiveling discharge chute

The 270° swiveling discharge chute with quick adjustable system discharges the material at a height of about 195 cm. A deflector allows you to adjust the direction of the discharged material for a proper loading onto vehicles. The generous dimensions and the angle of the discharge chute are developed, once again, to facilitate the discharge of chipping, avoiding clogging issues even when the material is green and fibrous.

Honda professional Engine

Reliability and functionality guaranteed over time

Hydraulic loading roller with adjustable speed

The toothed loading roller allows the transport of the material from the hopper into the GRIN shredding system.

The roller is made of very resistant steel and powered by a high-performance hydraulic pump.

An external control allows you to change the speed in order to adjust the amount of material to be processed according to the type

GRIN ANTIstress PRO system

The movement of the rollers is regulated by the GRIN ANTIstress PRO system: it automatically manages the backward movement of the rollers, allowing the material to move backward for a few centimeters and then resume the chopping process a few seconds later.

This electronic control is essential to maintain a high working speed even when the machine is overloaded.

The GRIN ANTIstress PRO system also allows 3 different settings depending on the material that is going to be processed.

GRIN ULTRACUT cutting system

The GRIN ULTRACUT cutting system is the heart of the machine. It consists of a set of knives placed on a closed cylindrical cutterhead.

On the outer part, some radial blades are designed to generate the airflow needed to eject the processed material.

The GRIN ULTRACUT cutterhead:

- takes full advantage of the engine power

- decreases clogging caused by overloading

- reduces the consumption of the machine

- guarantees incredible working spee

Compact hopper with maxi inlet

A convenient and large hopper allows the loading of bulky and leafy material. Entering the shredding system, the branches pass through a 30 cm wide inlet, that allows an extreme working speed.

Opening flap for maintenance

It only takes a few seconds to open the GRIN BIOCH100 DRIVE flap that allows you to access the heart of the machine and quickly perform ordinary and extraordinary maintenance.

Thanks to this system the operator has access to the cutting apparatus for blades maintenance but also to the counter-blade for adjustments. Moreover, it is possible to clean it in a fast, comfortable and safe way.

79 cm to access all gardens

The dimensions of BIOCH100 DRIVE allow the machine to access all gardens. Only 79 cm wide; it is easy to pass through pedestrian gates or tight spaces, driving the machine to the pruning area.

Space-saving transport

Folding the discharge chute with a quick command and thanks to its dimensions of 185 L x 79 W x 150 H cm (with folded discharge chute), GRIN BIOCH100 DRIVE can also be loaded on small vans or save space on bigger trucks.

Drive tractor wheels

The tractor wheels of BIOCH100 DRIVE are equipped with hydraulic engines.

The operator can start the self-propelled unit with two levers placed under the hopper that engage the forward or the reverse gear.

Compared to shredders with tracks, the wheels are gentler on lawn but allow anyway a good performance on slopes.

Pivoting wheels with swinging bracket

Thanks to the pivoting wheels, it is possible to move the machine easily.

They are mounted on a swinging bracket to adapt to the uneven terrain and increase safety and effectiveness in traction.

A lock allows to fix the movement of the pivoting wheel during transport or loading onto the van.